Would you like to see your presentation here, made available to a global audience of researchers?

Add your own presentation or have us affordably record your next conference.

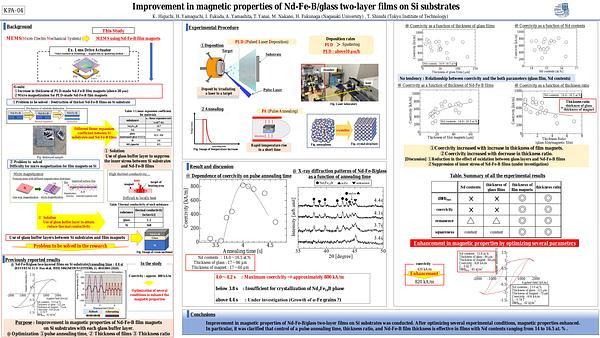

Although Nd-Fe-B thick-films with the thickness above 10 microns have been prepared by a sputtering and a PLD (Pulsed Laser Deposition) to develop the miniaturization of devices including a magnet 1, it is generally said that the sputtering is not suitable for a thick-film process due to the limitation of deposition rate and the PLD has difficulty in achieving the both of large deposition area together with high deposition rate. In the case of PLD-made Nd-Fe-B films, the area has been fixed at 5 mm square. Recently, we proposed a vacuum arc deposition with a rotational substrate system to obtain an isotropic Nd-Fe-B film magnet with a 20 mm square under a deposition rate above 10 μm/h. Furthermore, compositional and thickness distribution could be reduced to ±0.4 % and ±16 %, respectively. We, however, found that the squareness of a J-H loop and (BH)max drastically deteriorated at the edge of the sample. This contribution reports improvement of the deterioration by taking advantage of Nb additive to achieve target values of magnetic properties (Hcb > 420 kA/m, Br > 0.78 T, (BH)max> 62 kJ/m3) applied to a miniaturized device.

Figure 1 shows the relationship between coercivity (Hcb) and squareness of post-annealed Nd-Fe-B films after the vacuum arc deposition. Each symbol shows the properties of 5 mm square films cut from different area in a 20 mm square (Black circle, Black triangle: within 10 mm square from the center) and the edges (White circle, White triangle : outside of Black circle,Black triangle ). Usage of Nb additive enabled us to improve the squareness and suppress the dependence of deposition position. Moreover, Scherr’s equation using X-ray diffraction patterns reveled that the distribution of grain size due to the different deposition positions could be reduced by using Nb additive. It was also clarified that the target values except Hcb could be achieved.

References:

1 N. M. Dempsey et.al., Appl. Phys. Lett. Vol. A90, 092509(2007).

2 M. Nakano et al., IEEE Trans. Mag. vol.56, 7516303(2020).

Fig. 1 Relationship between coercivity and squareness of post-annealed films deposited on different positions.