Would you like to see your presentation here, made available to a global audience of researchers?

Add your own presentation or have us affordably record your next conference.

In the last years, the railway industry has been one of the leading sectors in the research of alternatives to reduce the costs associated with maintenance. The components of railway tracks suffer huge amounts of pressure that could compromise railway safety and must be revised, repaired and renew frequently according to strict criteria. In the case of the sleeper, the maximum stress allowed by the different authorities is in the order of ∼100 MPa 1 before substitution. Currently, the main testing procedures are based on visual inspection or in situ measurements, making maintenance procedures economically inefficient.

With the development of industry 4.0, researchers have been studying the fabrication of smart-sleepers capable of monitoring the sleeper structural stress in real-time 2. Current technology makes extensive use of expensive optical fiber based instruments 2,3. Thus, making it difficult to extend its use to big extensions of railway lines.

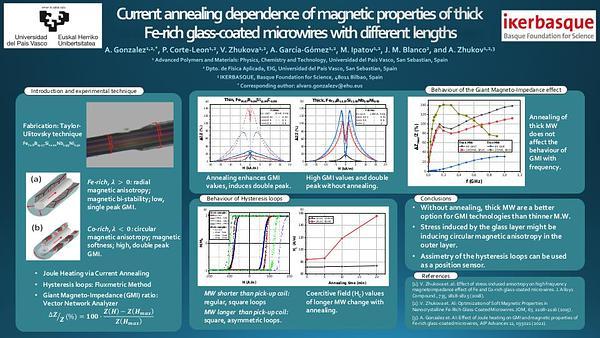

Magnetic microwires fabricated by the Taylor-Ulitovsky technique appear in this context as an alternative for smart-sleeper technology. The microwires obtained using this technique are characterized by their small cross section (d =0 .5-40 µm), environment insulation thanks to the glass-coating and high sensitivity to external stimuli 4. These properties, along with their cheap fabrication costs has motivated the study of this microwires for structural measurements in concrete structures similar to concrete sleepers 5.

In this work we show the possibility of glass coated magnetic microwires of working as railway monitorization devices. This is done by measuring the effect of longitudinal stress on the hysteresis loops of several Co- and Fe-rich microwires with different compositions. By analyzing the hysteresis loops, as shown in Fig 1 and Fig 2, we are able to obtain a calibration function that relates the coercitive field, Hc, with the applied stress over a wide applied stresses range.

References:

1 Parvez A., Foster, S. J., Engineering Structures, Vol 141, p 241-250, (2017).

2 Jing G. et al., Construction and Building Materials, Vol 271, 121533, (2021).

3 Butler et al., Structural Health Monitoring, Vol 17(3), p 635-653, (2018).

4 Corte-Leon P. et al, Journal of Alloys and Compounds, Vol 789, p 201-208. (2019)

5 Olivera, J., et al (2019. Sensors, Vol 19(21), 4685 (2019)

Figure 1: Response of wire Fe4.39 Co65.12 Si6.79 Cr8.88 Mo0.15 to stress a) Hysteresis loop evolution. b) Microwire calibration function.

Figure 2: Response of wire Fe66.99 Si6.45 Nb5.79 Ni1.13 upon to stress a) Hysteresis loop evolution. b) Microwire calibration function.